A wire rope can consist of different types of material.

- Uncoated steel wire rope

Wire ropes that have a relatively short life span (less than a year) and generally need to be discarded (replaced) because of damage can be made with uncoated material. Uncoated wire ropes are not always in stock.

- Galvanized steel wire rope

The biggest advantage of galvanized steel wire is its better resistance to corrosion. The zinc extends the life span of the wire rope in humid and corrosive environments. In addition, zinc also has a lubricating effect.

- Stainless steel wire rope

Stainless steel wire is highly resistant to corrosion and heat up to approximately 250°C. However, the resistance to fatigue is considerably less than that of uncoated and galvanized steel wires.

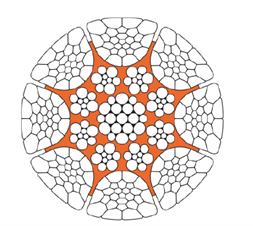

- Plastic-coated core

In some steel wire ropes, the core is coated with a plastic layer. The advantage: it lowers the wear between the core and the outer strands. This construction is also more stable, and a cable with a plastic-coated core has a high resistance to rotation around the axis as a result of a deflection angle.

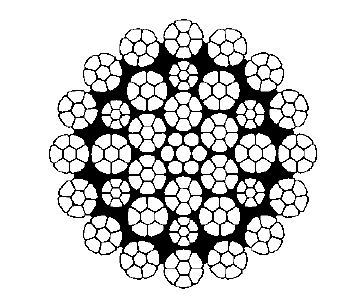

- Compacted strands

There are also steel cables with compacted strands. These strands have a high filler factor, as the spaces between the strands are filled as much as possible during manufacturing. A compacted cable has a higher breaking load and an increased resistance to destruction and chafing. However, the cable is stiffer and has a lower resistance to fatigue at lower loads.

- Swaged wire rope

A swaged wire rope is rounder than other ropes. As a result, a swaged rope has a better bearing surface and an increased breaking load.

Let us advise you

As you can see, just behind the composition of a steel wire rope is a world of variation. Curious about which steel wire rope is suitable for your application? Let us inform you. At Mennens, we have years of knowledge and expertise.

Read more

Knowledge articles

Discover the main concerns of steel wire ropes:

- The history of steel wire rope

- The composition of steel wire ropes

- The core

- The strands

- Materials

- End connections

- Breaking load, usage rate and workload

- How corrosion affects steel wire ropes

Services

Discover how Mennens can support you: