The Magnetic Rope Test is suggested every time the Visual Inspection is not enough for a correct wire rope evaluation.

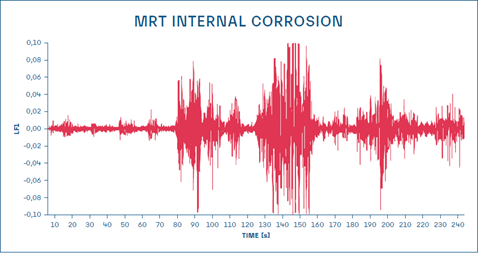

This picture shows a diagram corresponding to a magnetic rope test in a marine environment. The whole rope was covered with lubricant and was very difficult to perform an in-depth visual inspection.

The visual inspector did not find any problem and the rope has been declared in good conditions but, when a MRT has been performed, it highlighted a different condition.

The diagram reveals a very dangerous situation, there are some zones with a high peak concentration and this means that the rope is deeply corroded.

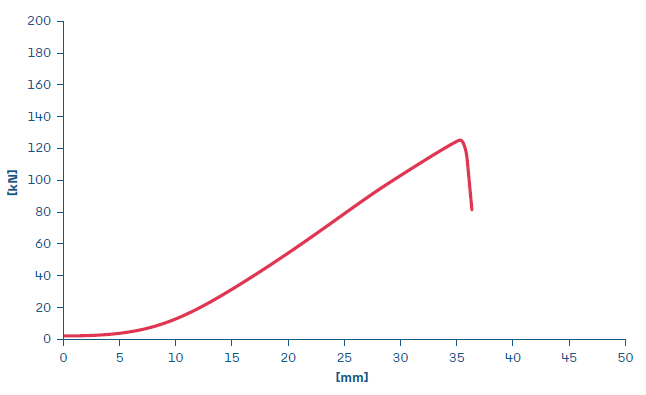

The rope has been immediately removed and a breaking test has been performed. The result shows that the residual load capacity was less than 1/3 of the nominal one (125kN vs. 400kN).

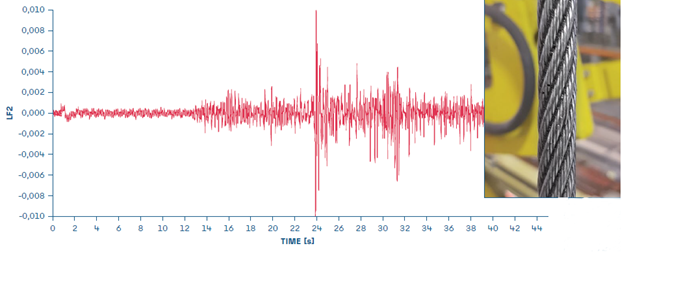

In this other picture the MRT diagram of a crane rope is shown. This plant is working 24/7 and the rope get damaged very quickly; for this reason the device is always mounted on it to ensure a continuous monitoring.

In this case it’s easy to find broken wires on the rope surface but it requires long plant stops. The MRT is useful to detect every defect on the rope, to monitor the situation and to schedule the plant stop and the rope replacement.

Conclusions

It is important to focus on the meaning of “visible”, which strongly depends on the inspection conditions, grease, speed, operator’s attention.

For external defect an MRT is not mandatory, but it is the only tool that can provide a quick and accurate assessment of whole rope conditions.

For internal defects, the situation changes. MRT is the only method claimed by regulations (EN12927, ISO4309).

When it is not possible to perform a Magnetic Rope Test, the inspector must evaluate the rope conditions just basing his assessment on the visual inspection and his own experience.

To have a clear vision of all the different modes of deterioration and the relative assessment methods we suggest you check on the ISO4309.

More about Magnetic Rope Testing?

Discover our articles about Magnetic Rope Testing (MRT):

- Rope inspection, safety and the ISO4309 regulation

- The EN12927, is your MRT device in compliance with the standard?

- Localized Fault VS Loss of Metallic Area

- MRT-training

- A permanent MRT system

- The magnetization curve of a steel wire rope

- How is MRT equipment made

- How to choose an MRT device

- How to develop customized magneto-inductive equipment